Model No.: EILS-TR-0418

Use: for Loading/Unloading of Tankers by Pumping

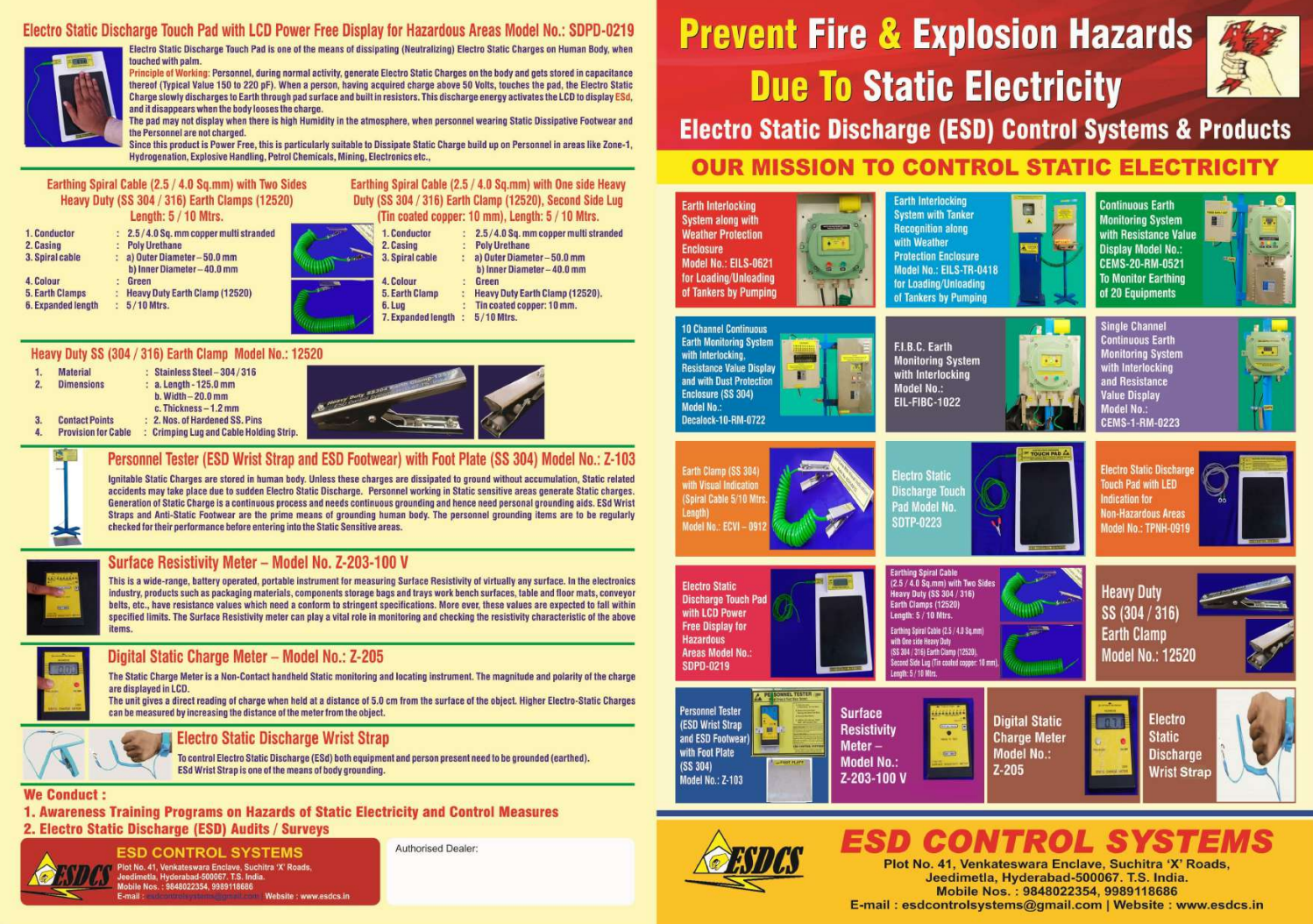

INTRODUCTION

Explosive atmospheres in the workplace can be caused by flammable gases, mists or vapors or by combustible dusts. Explosions can cause loss of life and serious injuries as well as significant damage.

Background

Explosive atmospheres can be caused by flammable gases, mists or by combustible dusts. If there is enough of the substance, mixed with air, then all it needs is a source of ignition to cause an explosion. Accumulated static charges on equipment and tanker while solvents are handled, readily provides this third parameter.

Explosion can cause loss of life and serious injuries as well as significant damage. Preventing releases of dangerous substances, which can create explosive atmospheres, and preventing sources of ignition are two widely used ways of reducing the risk. Using the correct equipment can greatly help this.

The Dangerous Substances and Explosive Atmospheres Regulation 2002 (DSEAR) place duties on employers to eliminate or control the risks from explosive atmospheres in the workplace. A summary of those requirements can be found below.

This page does not deal with intentional explosives such as those used in demolition work or blasting in quarries.

An explosive atmosphere is defined as a mixture of dangerous substances with air, under atmospheric condition, in the form of gases, vapors, mist or dust in which, after ignition has occurred, combustion spreads to the entire unburned mixture. An explosive atmosphere is an accumulation of gas, mist, dust or vapor, mixed with air, which has the potential to catch fire or explosion. An explosive atmosphere does not always result in an explosion, but if it caught fire the flames would quickly travel though it and if this happens in a confined space (e.g., in plant or equipment) the rapid spread of the flames or rise in pressure could also cause explosion atmospheric conditions are commonly referred to as ambient temperatures and pressures. That is to say temperatures of – 200C to 400C and pressures of 0.8 to 1.1 bar…

Many workplaces may contain, or have activities that produce, explosive or potentially explosive atmospheres. Examples include places where work activities create or release flammable gases or vapors, such as vehicle paint spraying, or in workplaces handling fine organic dusts such as grain flour or wood, classified as Zone-1.

Liquids

Liquids (such as petrol and other fuels) and solvents in industrial products (such as paint, ink, adhesives and cleaning fluids) give off flammable vapor which, when mixed with air, can ignite or explode. Flammable liquids are classed as:

Extremely flammable

Liquids which have a flash point lower than 00C and a boiling point (or, in the case of a boiling range, the initial boiling point) lower than or equal to 350C.

Highly flammable

Liquids which have a flash point below 210C but which are extremely flammable.

Flammable Dusts

Dusts can be produced from many everyday materials such as coal, wood, grain, sugar, certain metals and synthetic organic chemicals. A cloud of combustible dust in the air can explode violently if ignited.

Gases

Gases such as liquefied petroleum gas or methane. These are usually stored under pressure in cylinders and bulk containers. Uncontrolled releases can readily ignite or cause the cylinder to become a missile.

Solids

Solids include materials such as plastic foam, packaging, and textiles which can burn fiercely and give off dense black smoke, sometimes poisonous.

This manual provides complete information of installation, operation and maintenance procedures and instructions for operating Advanced Earth Interlocking System. Read this manual before attempting to install and operate EILS-TR-0418.

This manual contains essential safety information which supplements the safety features of the EILS-TR-0418. You must follow this instruction.

Each EILS-TR-0418 System consists of the following sub components or equipment:

EILS-TR-0418 is a system useful for controlling Static Electricity Discharges Hazardous areas in Bulk Drug, Chemical & Pharma and other industries handling inflammable liquids, solvents and explosive propellants. These systems continuously monitors Earth connectivity & prevents accumulation of static electricity and discharge during tanker un-loading and loading.

EILS-TR-0418 enables or disables power supply to existing transfer pump switching system. The pumps can only be switched “ON” manually for product transfer if the resistance to Ground (RG) from Tanker to Earth Connection is <= 10 Ohms. And the pump will be automatically stopped if there is by any chance Earth Failure or High Resistance is detected during product transfer.

The EILS-TR-0418 System continuously monitors the earth connection from Tanker to Earth Connection. It has RED, GREEN, YELLOW colored high bright LED indication systems indicating, clamp contact to tanker and earth loop check of less than 10 OHMS and STAND BY Mode RESPECTIVELY. Operator can be easily alerted to know the unsafe status of Transfer Process with this unique technology.

This unit is designed specially by incorporating Spark free switching mechanism works

With intrinsically safe ultra-low voltage & current feature. This system has highly sophisticated electronic sub-assemblies populated with high performance, long lasting and most reliable sub components from various reputed manufacturers.

The FLP enclosure meets industry standards, made out of Cast Aluminum with flame proof design, weather proof and certified by CMRI, Dhanbad. (Please find enclosed copy of certificate) and completely integrated unit is also tested for several Physical and Electrical tests like Burn-In test, Functional Testes, Mechanical Shock, Vibration, Drop, Dump etc. as desired by Industrial Applications.

The EILS-TR-0418 is a very important system wherever hazardous material is being transferred though tankers, bulk containers etc. this system has been designed in accordance

to the requirements of the industry studied and continual development over a period of 4 years.

The EILS-TR-0418 is user friendly System, very easy to install and operate and available for prompt delivery with additional accessories and alternative cabling solutions.

The EILS-TR-0418 ensures the highest possible levels of safe, positive earthing for road tanker during flammable transfer operations. Unlike conventional systems, the EILS-TR-0418 provides failsafe confirmation of the static earth condition using Industrial Grade Subcomponents and Electronics.

Modified version EILS-TR-0418 incorporates solvent tanker recognition system, i.e., the instrument switches on only when the clamp is hooked to stand alone tanker parked at unloading bay. The tanker body has typically 1000 to 5000 pF capacitance, and when the clamp is hooked to its body it takes measurement of this capacitance and if OK indicates with Green LEDs on top right and now is ready to operate as tanker earth interlock system. All other functions are as given above.

During unloading process, when S.S. hose is coupled to tanker and electrical power fails, the unit cannot be restarted. A special key operated magnetic switch is installed on right side of main FLP unit. By obtaining key from supervisory staff the system can be restarted.

On rare occasions if the solvent tanker is drenched due to heavy rains, the system may have to be started by magnetic key switch.

The above facility does not exist in other imported / indigenous models.

Standards as per

IS/IEC 60079-0: 2017

IS/IEC 60079-11:2011

Earth Interlock System: User friendly operating switches. No interruption in pumping system unless fault occurs. Self-standing powder coated M.S. Cabinet with two doors upper compartment houses main instrument and lower compartment houses the clamp and the flexible cable.

Main Console (Model: EILS-TR-0418) | Material | Flame Proof & Weather Proof Cast Aluminum alloy (LM-6) as per IP65 |

Dimensions | (300) W x (130) D x (500) H in mm approx. | |

Mounting | Pre-Mounted in Enclosure supplied | |

Weight | 12 Kgs. | |

ESD Earthling Clamp (Model: EILS-TR-0418) | Material | Complete Stainless-Steel Body with Two Tungsten Carbide Tips for captive connection to ground via tanker body., and Loaded with High Strength Spring |

Dimensions | (55) W x (70) D x (250) L in mm approx. | |

Weight | 1.25 Kgs. Approx. |

Main Console (Model: EILS-TR-0418) | Mounting & Installing location | Near Tanker unloading Point |

| Power Input | 230V 1PHASE |

| Operational Voltage | 12 Volts D.C |

| Power Consumption | < 10 Watts |

Power Input | 230V 1Phase. | |

CONTROL GEAR INTERFACE | Potential free N.O. contacts 5A capacity. | |

Cable Entries | 1.5mm Sq. x 4 Core armored cable leading to main monitoring unit. | |

ESD Earthling Clamp (Model: EILS-TR-0418) | Mounting & Installing location | Integrated part with Main Unit on Right Side Hook. With flexible cord. |

Cable Entries | 6mm PVC Hose | |

Earth Loop Monitoring | Constant Current | 20 mA maximum D.C through 0.6 Volts source system |

Earth PASS Monitoring Range | Min. Ohms. | Earth Loop Resistance is <=10 Ohms. |

Main Console (Model: AEILS ECL08) | MS. Industrial Enclosure | Operating Temp.: -10 To + 750C |

Earthing Clamp (Model: AEILS ECL08) | SS. Enclosure | Operating Temp.: -10 To + 750C |

Main Console (Model: EILS-TR-0418) | 3 Cables | 1. Earthing Wire & Monitoring Wires to Earth Pit Connection. (3 core) 2. 4 core Armored cable & Pump Inhibit signal 2+2 POWER 3. Flexible cable to Earthing Clamp |

ESD Earthing Clamp (Model: EILS-TR-0418) | 1 Cable | Flexible cable to Main Console |

Follow the Steps given below with same sequence to operate the instrument properly.

FOR UNLOADING THE TANKER

STEP | OPERATION | MODE | INDICATION |

Normal position | standby | Left Yellow LED – ON Remaining LEDs OFF | |

1 | Green button push to ON | Instrument ON and standby OFF | Interlock Blue LED –ON Top Red – ON Remaining OFF |

2 | Connect Clamp to the Tanker | Instrument ON and standby + Tanker Recognition | Auto Yellow LED – ON Earth Loop Green LED – OK |

Note: – Now the tanker is grounded. Connect hose to the tanker and take all ESD Precautions and Switch on the Pump.

After Unloading the tanker Follow the steps given below for disconnecting Interlocking system

1 | Red button push once to switch OFF | Instrument OFF and standby mode ON | Left – Yellow LED ON |

2 | Remove the Clamp | Instrument and standby mode ON | Left – Yellow LED ON |

After Completion of un-loading operation and decoupling of hoses, vehicle ready for deporting. The EILS-TR-0418 unit can be brought to standby mode by Removing hand clamp from vehicle body.

All transit mode conditions will repeat till ESD clamp jaw is closed and returns to standby mode.

Caution: Changes or modifications to this product not expressly approved by ESDCS, or operation of this product in any way other than as detailed by this User Manual, could void your manufacturer warranty. (Please refer to the enclosed warranty terms & Conditions.)

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any form or by any means like electronic or mechanical, for any purpose without the express written permission of ESD CONTROL SYSTEMS, HYDERABAD.

Unpacking and inspection

Remove all packing materials and protective covers and check EILS-TR-0418 for damage. If the EILS-TR-0418 is damaged,

Notify your supplier and the carrier in writing within three days; state the Item Number of the EILS-TR-0418 together with your order number and your supplier’s invoice number. Retain all packing materials for inspection. Do not use the EILS-TR-0418 till further communication from ESD Control Systems.

Installation

The EILS-TR-0418 unit should be mounted as close as possible to the point at which the tanker unloading/loading is done. Preferably on left side of solvent inlet pipe flange set up

Connecting EILS-TR-0418 to existing PUMP control Switchgear system / to the Electrical Circuit.

Standard AC 230 V input is to be given to the 2/3 Core 1 mm2 PVC Cable. A loop is to be established by connecting all control points provided for each pump Starter in the panel and the same is to be connected to EILS-TR-0418, 230 Volts control lines up to ten Nos provided through slave contactor.

WARNING: Ensure that the electrical installation of the EILS-TR-0418 conforms with your local and national safety requirements. It must be connected to a suitably fused and protected electrical supply and a suitable electrical earth point.

MATERIALS REQUIREMENT:

*All and any type of Damage to any part of the unit including Sub Systems supplied caused by any reason would not be covered by the manufacturer’s warranty.

This data is provided for general information and material comparison. The potential user should perform tests to determine the product’s performance and suitability in the intended application. Final determination of the fitness of the product for any particular application is the responsibility of the buyer.

INTRODUCTION

Explosive atmospheres in the workplace can be caused by flammable gases, mists or vapors or by combustible dusts. Explosions can cause loss of life and serious injuries as well as significant damage.

Background

Explosive atmospheres can be caused by flammable gases, mists or by combustible dusts. If there is enough of the substance, mixed with air, then all it needs is a source of ignition to cause an explosion. Accumulated static charges on equipment and tanker while solvents are handled, readily provides this third parameter.

Explosion can cause loss of life and serious injuries as well as significant damage. Preventing releases of dangerous substances, which can create explosive atmospheres, and preventing sources of ignition are two widely used ways of reducing the risk. Using the correct equipment can greatly help this.

The Dangerous Substances and Explosive Atmospheres Regulation 2002 (DSEAR) place duties on employers to eliminate or control the risks from explosive atmospheres in the workplace. A summary of those requirements can be found below.

This page does not deal with intentional explosives such as those used in demolition work or blasting in quarries.

An explosive atmosphere is defined as a mixture of dangerous substances with air, under atmospheric condition, in the form of gases, vapors, mist or dust in which, after ignition has occurred, combustion spreads to the entire unburned mixture. An explosive atmosphere is an accumulation of gas, mist, dust or vapor, mixed with air, which has the potential to catch fire or explosion. An explosive atmosphere does not always result in an explosion, but if it caught fire the flames would quickly travel though it and if this happens in a confined space (e.g., in plant or equipment) the rapid spread of the flames or rise in pressure could also cause explosion atmospheric conditions are commonly referred to as ambient temperatures and pressures. That is to say temperatures of – 200C to 400C and pressures of 0.8 to 1.1 bar…

Many workplaces may contain, or have activities that produce, explosive or potentially explosive atmospheres. Examples include places where work activities create or release flammable gases or vapors, such as vehicle paint spraying, or in workplaces handling fine organic dusts such as grain flour or wood, classified as Zone-1.

Liquids

Liquids (such as petrol and other fuels) and solvents in industrial products (such as paint, ink, adhesives and cleaning fluids) give off flammable vapor which, when mixed with air, can ignite or explode. Flammable liquids are classed as:

Extremely flammable

Liquids which have a flash point lower than 00C and a boiling point (or, in the case of a boiling range, the initial boiling point) lower than or equal to 350C.

Highly flammable

Liquids which have a flash point below 210C but which are extremely flammable.

Flammable Dusts

Dusts can be produced from many everyday materials such as coal, wood, grain, sugar, certain metals and synthetic organic chemicals. A cloud of combustible dust in the air can explode violently if ignited.

Gases

Gases such as liquefied petroleum gas or methane. These are usually stored under pressure in cylinders and bulk containers. Uncontrolled releases can readily ignite or cause the cylinder to become a missile.

Solids

Solids include materials such as plastic foam, packaging, and textiles which can burn fiercely and give off dense black smoke, sometimes poisonous.

This manual provides complete information of installation, operation and maintenance procedures and instructions for operating Advanced Earth Interlocking System. Read this manual before attempting to install and operate EILS-TR-0418.

This manual contains essential safety information which supplements the safety features of the EILS-TR-0418. You must follow this instruction.

Each EILS-TR-0418 System consists of the following sub components or equipment:

EILS-TR-0418 is a system useful for controlling Static Electricity Discharges Hazardous areas in Bulk Drug, Chemical & Pharma and other industries handling inflammable liquids, solvents and explosive propellants. These systems continuously monitors Earth connectivity & prevents accumulation of static electricity and discharge during tanker un-loading and loading.

EILS-TR-0418 enables or disables power supply to existing transfer pump switching system. The pumps can only be switched “ON” manually for product transfer if the resistance to Ground (RG) from Tanker to Earth Connection is <= 10 Ohms. And the pump will be automatically stopped if there is by any chance Earth Failure or High Resistance is detected during product transfer.

The EILS-TR-0418 System continuously monitors the earth connection from Tanker to Earth Connection. It has RED, GREEN, YELLOW colored high bright LED indication systems indicating, clamp contact to tanker and earth loop check of less than 10 OHMS and STAND BY Mode RESPECTIVELY. Operator can be easily alerted to know the unsafe status of Transfer Process with this unique technology.

This unit is designed specially by incorporating Spark free switching mechanism works

With intrinsically safe ultra-low voltage & current feature. This system has highly sophisticated electronic sub-assemblies populated with high performance, long lasting and most reliable sub components from various reputed manufacturers.

The FLP enclosure meets industry standards, made out of Cast Aluminum with flame proof design, weather proof and certified by CMRI, Dhanbad. (Please find enclosed copy of certificate) and completely integrated unit is also tested for several Physical and Electrical tests like Burn-In test, Functional Testes, Mechanical Shock, Vibration, Drop, Dump etc. as desired by Industrial Applications.

The EILS-TR-0418 is a very important system wherever hazardous material is being transferred though tankers, bulk containers etc. this system has been designed in accordance

to the requirements of the industry studied and continual development over a period of 4 years.

The EILS-TR-0418 is user friendly System, very easy to install and operate and available for prompt delivery with additional accessories and alternative cabling solutions.

The EILS-TR-0418 ensures the highest possible levels of safe, positive earthing for road tanker during flammable transfer operations. Unlike conventional systems, the EILS-TR-0418 provides failsafe confirmation of the static earth condition using Industrial Grade Subcomponents and Electronics.

Modified version EILS-TR-0418 incorporates solvent tanker recognition system, i.e., the instrument switches on only when the clamp is hooked to stand alone tanker parked at unloading bay. The tanker body has typically 1000 to 5000 pF capacitance, and when the clamp is hooked to its body it takes measurement of this capacitance and if OK indicates with Green LEDs on top right and now is ready to operate as tanker earth interlock system. All other functions are as given above.

During unloading process, when S.S. hose is coupled to tanker and electrical power fails, the unit cannot be restarted. A special key operated magnetic switch is installed on right side of main FLP unit. By obtaining key from supervisory staff the system can be restarted.

On rare occasions if the solvent tanker is drenched due to heavy rains, the system may have to be started by magnetic key switch.

The above facility does not exist in other imported / indigenous models.

Earth Interlock System: User friendly operating switches. No interruption in pumping system unless fault occurs. Self-standing powder coated M.S. Cabinet with two doors upper compartment houses main instrument and lower compartment houses the clamp and the flexible cable.

Main Console (Model: EILS-TR-0418) | Material | Flame Proof & Weather Proof Cast Aluminum alloy (LM-6) as per IP65 |

Dimensions | (300) W x (130) D x (500) H in mm approx. | |

Mounting | Pre-Mounted in Enclosure supplied | |

Weight | 12 Kgs. | |

ESD Earthling Clamp (Model: EILS-TR-0418) | Material | Complete Stainless-Steel Body with Two Tungsten Carbide Tips for captive connection to ground via tanker body., and Loaded with High Strength Spring |

Dimensions | (55) W x (70) D x (250) L in mm approx. | |

Weight | 1.25 Kgs. Approx. |

Main Console (Model: EILS-TR-0418) | Mounting & Installing location | Near Tanker unloading Point |

| Power Input | 230V 1PHASE |

| Operational Voltage | 12 Volts D.C |

| Power Consumption | < 10 Watts |

Power Input | 230V 1Phase. | |

CONTROL GEAR INTERFACE | Potential free N.O. contacts 5A capacity. | |

Cable Entries | 1.5mm Sq. x 4 Core armored cable leading to main monitoring unit. | |

ESD Earthling Clamp (Model: EILS-TR-0418) | Mounting & Installing location | Integrated part with Main Unit on Right Side Hook. With flexible cord. |

Cable Entries | 6mm PVC Hose | |

Earth Loop Monitoring | Constant Current | 20 mA maximum D.C through 0.6 Volts source system |

Earth PASS Monitoring Range | Min. Ohms. | Earth Loop Resistance is <=10 Ohms. |

Main Console (Model: AEILS ECL08) | MS. Industrial Enclosure | Operating Temp.: -10 To + 750C |

Earthing Clamp (Model: AEILS ECL08) | SS. Enclosure | Operating Temp.: -10 To + 750C |

Main Console (Model: EILS-TR-0418) | 3 Cables | 1. Earthing Wire & Monitoring Wires to Earth Pit Connection. (3 core) 2. 4 core Armored cable & Pump Inhibit signal 2+2 POWER 3. Flexible cable to Earthing Clamp |

ESD Earthing Clamp (Model: EILS-TR-0418) | 1 Cable | Flexible cable to Main Console |

Follow the Steps given below with same sequence to operate the instrument properly.

FOR UNLOADING THE TANKER

STEP | OPERATION | MODE | INDICATION |

Normal position | standby | Left Yellow LED – ON Remaining LEDs OFF | |

1 | Green button push to ON | Instrument ON and standby OFF | Interlock Blue LED –ON Top Red – ON Remaining OFF |

2 | Connect Clamp to the Tanker | Instrument ON and standby + Tanker Recognition | Auto Yellow LED – ON Earth Loop Green LED – OK |

Note: – Now the tanker is grounded. Connect hose to the tanker and take all ESD Precautions and Switch on the Pump.

After Unloading the tanker Follow the steps given below for disconnecting Interlocking system

1 | Red button push once to switch OFF | Instrument OFF and standby mode ON | Left – Yellow LED ON |

2 | Remove the Clamp | Instrument and standby mode ON | Left – Yellow LED ON |

After Completion of un-loading operation and decoupling of hoses, vehicle ready for deporting. The EILS-TR-0418 unit can be brought to standby mode by Removing hand clamp from vehicle body.

All transit mode conditions will repeat till ESD clamp jaw is closed and returns to standby mode.

Caution: Changes or modifications to this product not expressly approved by ESDCS, or operation of this product in any way other than as detailed by this User Manual, could void your manufacturer warranty. (Please refer to the enclosed warranty terms & Conditions.)

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any form or by any means like electronic or mechanical, for any purpose without the express written permission of ESD CONTROL SYSTEMS, HYDERABAD.

Unpacking and inspection

Remove all packing materials and protective covers and check EILS-TR-0418 for damage. If the EILS-TR-0418 is damaged,

Notify your supplier and the carrier in writing within three days; state the Item Number of the EILS-TR-0418 together with your order number and your supplier’s invoice number. Retain all packing materials for inspection. Do not use the EILS-TR-0418 till further communication from ESD Control Systems.

Installation

The EILS-TR-0418 unit should be mounted as close as possible to the point at which the tanker unloading/loading is done. Preferably on left side of solvent inlet pipe flange set up

Connecting EILS-TR-0418 to existing PUMP control Switchgear system / to the Electrical Circuit.

Standard AC 230 V input is to be given to the 2/3 Core 1 mm2 PVC Cable. A loop is to be established by connecting all control points provided for each pump Starter in the panel and the same is to be connected to EILS-TR-0418, 230 Volts control lines up to ten Nos provided through slave contactor.

WARNING: Ensure that the electrical installation of the EILS-TR-0418 conforms with your local and national safety requirements. It must be connected to a suitably fused and protected electrical supply and a suitable electrical earth point.

MATERIALS REQUIREMENT:

*All and any type of Damage to any part of the unit including Sub Systems supplied caused by any reason would not be covered by the manufacturer’s warranty.

This data is provided for general information and material comparison. The potential user should perform tests to determine the product’s performance and suitability in the intended application. Final determination of the fitness of the product for any particular application is the responsibility of the buyer.

INTRODUCTION

Explosive atmospheres in the workplace can be caused by flammable gases, mists or vapors or by combustible dusts. Explosions can cause loss of life and serious injuries as well as significant damage.

Background

Explosive atmospheres can be caused by flammable gases, mists or by combustible dusts. If there is enough of the substance, mixed with air, then all it needs is a source of ignition to cause an explosion. Accumulated static charges on equipment and tanker while solvents are handled, readily provides this third parameter.

Explosion can cause loss of life and serious injuries as well as significant damage. Preventing releases of dangerous substances, which can create explosive atmospheres, and preventing sources of ignition are two widely used ways of reducing the risk. Using the correct equipment can greatly help this.

The Dangerous Substances and Explosive Atmospheres Regulation 2002 (DSEAR) place duties on employers to eliminate or control the risks from explosive atmospheres in the workplace. A summary of those requirements can be found below.

This page does not deal with intentional explosives such as those used in demolition work or blasting in quarries.

An explosive atmosphere is defined as a mixture of dangerous substances with air, under atmospheric condition, in the form of gases, vapors, mist or dust in which, after ignition has occurred, combustion spreads to the entire unburned mixture. An explosive atmosphere is an accumulation of gas, mist, dust or vapor, mixed with air, which has the potential to catch fire or explosion. An explosive atmosphere does not always result in an explosion, but if it caught fire the flames would quickly travel though it and if this happens in a confined space (e.g., in plant or equipment) the rapid spread of the flames or rise in pressure could also cause explosion atmospheric conditions are commonly referred to as ambient temperatures and pressures. That is to say temperatures of – 200C to 400C and pressures of 0.8 to 1.1 bar…

Many workplaces may contain, or have activities that produce, explosive or potentially explosive atmospheres. Examples include places where work activities create or release flammable gases or vapors, such as vehicle paint spraying, or in workplaces handling fine organic dusts such as grain flour or wood, classified as Zone-1.

Liquids

Liquids (such as petrol and other fuels) and solvents in industrial products (such as paint, ink, adhesives and cleaning fluids) give off flammable vapor which, when mixed with air, can ignite or explode. Flammable liquids are classed as:

Extremely flammable

Liquids which have a flash point lower than 00C and a boiling point (or, in the case of a boiling range, the initial boiling point) lower than or equal to 350C.

Highly flammable

Liquids which have a flash point below 210C but which are extremely flammable.

Flammable Dusts

Dusts can be produced from many everyday materials such as coal, wood, grain, sugar, certain metals and synthetic organic chemicals. A cloud of combustible dust in the air can explode violently if ignited.

Gases

Gases such as liquefied petroleum gas or methane. These are usually stored under pressure in cylinders and bulk containers. Uncontrolled releases can readily ignite or cause the cylinder to become a missile.

Solids

Solids include materials such as plastic foam, packaging, and textiles which can burn fiercely and give off dense black smoke, sometimes poisonous.

This manual provides complete information of installation, operation and maintenance procedures and instructions for operating Advanced Earth Interlocking System. Read this manual before attempting to install and operate EILS-TR-0418.

This manual contains essential safety information which supplements the safety features of the EILS-TR-0418. You must follow this instruction.

Each EILS-TR-0418 System consists of the following sub components or equipment:

EILS-TR-0418 is a system useful for controlling Static Electricity Discharges Hazardous areas in Bulk Drug, Chemical & Pharma and other industries handling inflammable liquids, solvents and explosive propellants. These systems continuously monitors Earth connectivity & prevents accumulation of static electricity and discharge during tanker un-loading and loading.

EILS-TR-0418 enables or disables power supply to existing transfer pump switching system. The pumps can only be switched “ON” manually for product transfer if the resistance to Ground (RG) from Tanker to Earth Connection is <= 10 Ohms. And the pump will be automatically stopped if there is by any chance Earth Failure or High Resistance is detected during product transfer.

The EILS-TR-0418 System continuously monitors the earth connection from Tanker to Earth Connection. It has RED, GREEN, YELLOW colored high bright LED indication systems indicating, clamp contact to tanker and earth loop check of less than 10 OHMS and STAND BY Mode RESPECTIVELY. Operator can be easily alerted to know the unsafe status of Transfer Process with this unique technology.

This unit is designed specially by incorporating Spark free switching mechanism works

With intrinsically safe ultra-low voltage & current feature. This system has highly sophisticated electronic sub-assemblies populated with high performance, long lasting and most reliable sub components from various reputed manufacturers.

The FLP enclosure meets industry standards, made out of Cast Aluminum with flame proof design, weather proof and certified by CMRI, Dhanbad. (Please find enclosed copy of certificate) and completely integrated unit is also tested for several Physical and Electrical tests like Burn-In test, Functional Testes, Mechanical Shock, Vibration, Drop, Dump etc. as desired by Industrial Applications.

The EILS-TR-0418 is a very important system wherever hazardous material is being transferred though tankers, bulk containers etc. this system has been designed in accordance

to the requirements of the industry studied and continual development over a period of 4 years.

The EILS-TR-0418 is user friendly System, very easy to install and operate and available for prompt delivery with additional accessories and alternative cabling solutions.

The EILS-TR-0418 ensures the highest possible levels of safe, positive earthing for road tanker during flammable transfer operations. Unlike conventional systems, the EILS-TR-0418 provides failsafe confirmation of the static earth condition using Industrial Grade Subcomponents and Electronics.

Modified version EILS-TR-0418 incorporates solvent tanker recognition system, i.e., the instrument switches on only when the clamp is hooked to stand alone tanker parked at unloading bay. The tanker body has typically 1000 to 5000 pF capacitance, and when the clamp is hooked to its body it takes measurement of this capacitance and if OK indicates with Green LEDs on top right and now is ready to operate as tanker earth interlock system. All other functions are as given above.

During unloading process, when S.S. hose is coupled to tanker and electrical power fails, the unit cannot be restarted. A special key operated magnetic switch is installed on right side of main FLP unit. By obtaining key from supervisory staff the system can be restarted.

On rare occasions if the solvent tanker is drenched due to heavy rains, the system may have to be started by magnetic key switch.

The above facility does not exist in other imported / indigenous models.

Earth Interlock System: User friendly operating switches. No interruption in pumping system unless fault occurs. Self-standing powder coated M.S. Cabinet with two doors upper compartment houses main instrument and lower compartment houses the clamp and the flexible cable.

Main Console (Model: EILS-TR-0418) | Material | Flame Proof & Weather Proof Cast Aluminum alloy (LM-6) as per IP65 |

Dimensions | (300) W x (130) D x (500) H in mm approx. | |

Mounting | Pre-Mounted in Enclosure supplied | |

Weight | 12 Kgs. | |

ESD Earthling Clamp (Model: EILS-TR-0418) | Material | Complete Stainless-Steel Body with Two Tungsten Carbide Tips for captive connection to ground via tanker body., and Loaded with High Strength Spring |

Dimensions | (55) W x (70) D x (250) L in mm approx. | |

Weight | 1.25 Kgs. Approx. |

Main Console (Model: EILS-TR-0418) | Mounting & Installing location | Near Tanker unloading Point |

| Power Input | 230V 1PHASE |

| Operational Voltage | 12 Volts D.C |

| Power Consumption | < 10 Watts |

Power Input | 230V 1Phase. | |

CONTROL GEAR INTERFACE | Potential free N.O. contacts 5A capacity. | |

Cable Entries | 1.5mm Sq. x 4 Core armored cable leading to main monitoring unit. | |

ESD Earthling Clamp (Model: EILS-TR-0418) | Mounting & Installing location | Integrated part with Main Unit on Right Side Hook. With flexible cord. |

Cable Entries | 6mm PVC Hose | |

Earth Loop Monitoring | Constant Current | 20 mA maximum D.C through 0.6 Volts source system |

Earth PASS Monitoring Range | Min. Ohms. | Earth Loop Resistance is <=10 Ohms. |

Main Console (Model: AEILS ECL08) | MS. Industrial Enclosure | Operating Temp.: -10 To + 750C |

Earthing Clamp (Model: AEILS ECL08) | SS. Enclosure | Operating Temp.: -10 To + 750C |

Main Console (Model: EILS-TR-0418) | 3 Cables | 1. Earthing Wire & Monitoring Wires to Earth Pit Connection. (3 core) 2. 4 core Armored cable & Pump Inhibit signal 2+2 POWER 3. Flexible cable to Earthing Clamp |

ESD Earthing Clamp (Model: EILS-TR-0418) | 1 Cable | Flexible cable to Main Console |

Follow the Steps given below with same sequence to operate the instrument properly.

FOR UNLOADING THE TANKER

STEP | OPERATION | MODE | INDICATION |

Normal position | standby | Left Yellow LED – ON Remaining LEDs OFF | |

1 | Green button push to ON | Instrument ON and standby OFF | Interlock Blue LED –ON Top Red – ON Remaining OFF |

2 | Connect Clamp to the Tanker | Instrument ON and standby + Tanker Recognition | Auto Yellow LED – ON Earth Loop Green LED – OK |

Note: – Now the tanker is grounded. Connect hose to the tanker and take all ESD Precautions and Switch on the Pump.

After Unloading the tanker Follow the steps given below for disconnecting Interlocking system

1 | Red button push once to switch OFF | Instrument OFF and standby mode ON | Left – Yellow LED ON |

2 | Remove the Clamp | Instrument and standby mode ON | Left – Yellow LED ON |

After Completion of un-loading operation and decoupling of hoses, vehicle ready for deporting. The EILS-TR-0418 unit can be brought to standby mode by Removing hand clamp from vehicle body.

All transit mode conditions will repeat till ESD clamp jaw is closed and returns to standby mode.

Caution: Changes or modifications to this product not expressly approved by ESDCS, or operation of this product in any way other than as detailed by this User Manual, could void your manufacturer warranty. (Please refer to the enclosed warranty terms & Conditions.)

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any form or by any means like electronic or mechanical, for any purpose without the express written permission of ESD CONTROL SYSTEMS, HYDERABAD.

Unpacking and inspection

Remove all packing materials and protective covers and check EILS-TR-0418 for damage. If the EILS-TR-0418 is damaged,

Notify your supplier and the carrier in writing within three days; state the Item Number of the EILS-TR-0418 together with your order number and your supplier’s invoice number. Retain all packing materials for inspection. Do not use the EILS-TR-0418 till further communication from ESD Control Systems.

Installation

The EILS-TR-0418 unit should be mounted as close as possible to the point at which the tanker unloading/loading is done. Preferably on left side of solvent inlet pipe flange set up

Connecting EILS-TR-0418 to existing PUMP control Switchgear system / to the Electrical Circuit.

Standard AC 230 V input is to be given to the 2/3 Core 1 mm2 PVC Cable. A loop is to be established by connecting all control points provided for each pump Starter in the panel and the same is to be connected to EILS-TR-0418, 230 Volts control lines up to ten Nos provided through slave contactor.

WARNING: Ensure that the electrical installation of the EILS-TR-0418 conforms with your local and national safety requirements. It must be connected to a suitably fused and protected electrical supply and a suitable electrical earth point.

MATERIALS REQUIREMENT:

*All and any type of Damage to any part of the unit including Sub Systems supplied caused by any reason would not be covered by the manufacturer’s warranty.

This data is provided for general information and material comparison. The potential user should perform tests to determine the product’s performance and suitability in the intended application. Final determination of the fitness of the product for any particular application is the responsibility of the buyer.

ESD Control Systems is a leader in certified advanced ESD product solutions and offers safety audit services, accident investigations, learning, and Training Programs – catering to the Pharmaceutical, Chemical, Defense, and Space and Electronics industries. ESD Control Systems’ Mission is to be the Static Dissipation Solution Provider for the World

ESD Control Systems is a leader in certified advanced ESD product solutions and offers safety audit services, accident investigations, learning, and Training Programs – catering to the Pharmaceutical, Chemical, Defense, and Space and Electronics industries. ESD Control Systems’ Mission is to be the Static Dissipation Solution Provider for the World

WhatsApp us