Static electricity at a fundamental level, is an imbalance of electric charges within or on the surface of a material. It occurs when certain materials are rubbed against each other, causing electrons to transfer from one material to the other. This transfer of electrons results in one material becoming positively charged and the other becoming negatively charged.

Static electricity is important to understand for several reasons, such as the shock you receive when touching a metal object after walking on a carpet, the clinging of clothes together after being dried in a dryer, or the attraction of dust particles to a TV screen.

Static electricity principles are applied for use in certain industrial applications, such as in electrostatic painting, where it is used to apply a coating to surfaces, and in electrostatic precipitators to remove particulate matter from industrial exhaust gases.

While may be favourable in certain situations, one of the most significant risks that Static electricity poses is in the explosive or flammable environments where a charge separation can cause significant Hazard to personnel and or equipment. This is where ESD Control Systems’ products and solutions come into play offering hazard monitoring and prevention. The hazard situations include environments where flammable gases or liquids are present. Generation of electrostatic discharge (sparks) could ignite the flammable gases or liquids, causing instant fires or explosions that are fatal. Oftentimes, these cannot be diagnosed or root caused effectively due to wide scale destructions these explosions may cause. Understanding Static electricity and circumstances when and how it is generated is crucial to designing safety measures to prevent such catastrophic incidents. The challenge for quality and safety organizations across industries is awareness about impacts of Static electricity and how to contain it. ESD Control Systems has pioneered this area for over several decades to provide need based (custom) instrumentation and solutions to a variety of industries and applications.

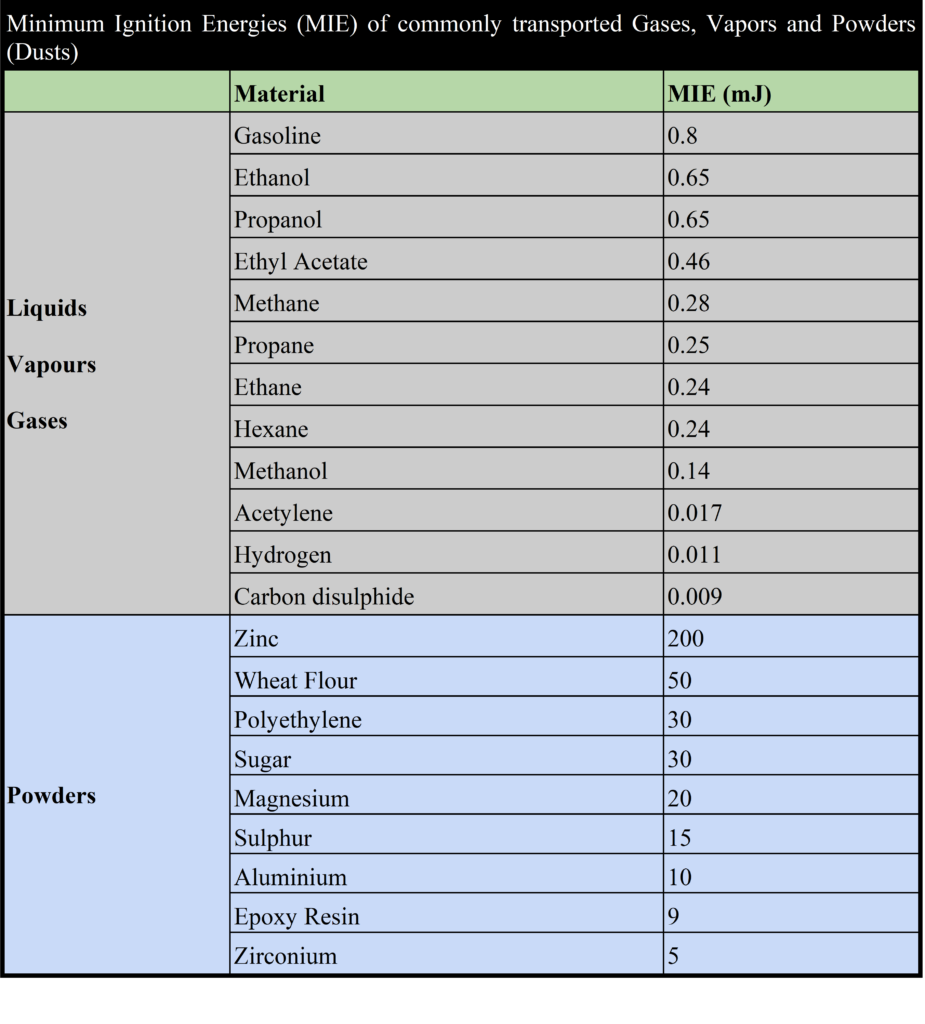

The presence of Static electricity in certain conditions may result in electric discharges, causing fires and explosions in hazardous locations. The question remains if an electrostatic spark is generated in a flammable atmosphere, does this (spark) energy that is released will bring about ignition. The answer to this lies for safety and process engineers in understanding Minimum Ignition Energy (MIE) of the flammable environment (Liquids, Vapor gases or Powders) they are dealing with and the possibility for such energy to be present in such an environment. Below table illustrates that with a few common examples.

It is interesting to note that static discharge from a human being may reach 60 mJ or more. A safety precaution with humans involved is to consider the human body capable of igniting a flammable environment with an MIE equal to 100 mJ or lower. A spark that is perceivable to the touch has around 20 mJ.

The energy levels produced in a given environment is a function of the process of charge separation, accumulation, and discharge. This combination gives the risk associated with static charges on flammable and combustible liquids. Good conductors are the best electrostatic generators, but this property allows them to discharge charges quickly. However, the Low conductivity liquids cannot discharge swiftly and they accumulate electrostatic charges, making them ‘static accumulators’. For this reason, the low conductivity products are the most dangerous. For example, ungrounded conductive objects such as truck tankers which are on rubber tires receiving charged liquids such as petroleum and liquids of highly refined products are typically static accumulators.

With increase in static accumulation, static potential increases, giving rise to an electric field. As electric field intensity reaches above 3kV/mm, which is the dielectric strength of air, sparks may occur leading to explosion.

In addition to the above, the presence of oxygen in the flammable environment also aids the explosion process. For this reason, use of inert gases such as Nitrogen is preferred.

Given the complex nature of circumstances that may potentially contribute to unsafe environments, ESD Control Systems could help advise based on detailed assessments the best course of action and path to eliminating static electricity hazards.

ESD Control Systems is a leader in certified advanced ESD product solutions and offers safety audit services, accident investigations, learning, and Training Programs – catering to the Pharmaceutical, Chemical, Defense, and Space and Electronics industries. ESD Control Systems’ Mission is to be the Static Dissipation Solution Provider for the World

ESD Control Systems is a leader in certified advanced ESD product solutions and offers safety audit services, accident investigations, learning, and Training Programs – catering to the Pharmaceutical, Chemical, Defense, and Space and Electronics industries. ESD Control Systems’ Mission is to be the Static Dissipation Solution Provider for the World

WhatsApp us